MP75 is a plaster that allows you to create smoothed, freely structured or levelled surfaces for interior walls. As a single-layer plaster for all kinds of masonry as well as stable plasterable substrates.

- From the cellar right up to the roof, suitable for all rooms with usual levels of room humidity including domestic kitchens and bathrooms (e.g. WCs in schools and bathrooms in hotels, hospitals, residential care and nursing homes)

- As a substrate for tiles, finishing plasters, coatings or wallpapers

Application

Substrate and pretreatment

Clean the substrate from dust and loose parts, ensuring that the surface is smooth. All substrates must be stable, dry, even and free of grease and dust as well as free of any residual substances that may reduce the

adhesion. Prime according to the substrate type.

Machines / equipment

PFT mixing pump G 4 / G 5

■ Stator D6-3

■ Rotor D6-3

■ Mortar hoses Ø 25 mm

■ Wet mortar pumping distance up to 30 m

Conveyors

PFT SILOMAT trans plus 100 (up to distances of 100 m)

PFT SILOMAT trans plus 140 (up to distances of 140 m)

Delivery rate for each 20 kg/min.

Mixing

Mix the contents of one bag with approximately 19 litres of clean water without further additions using a clean mixing paddle until an application-ready consistency is achieved.

Machine application

Adjust the water feed to achieve a lean mortar consistence (approx. 1 bar /metre mortar hose). Depending on the temperature, breaks in spraying not exceeding 10 to 15 minutes are possible. Clean the machine and hoses with longer breaks/interruptions in application.

Application

Apply the plaster on the wall within 20 mins of mixing. Level with a h or straight edge. After the initial setting has commenced, level with a feather edge and align the corners. If required, the surface can be reworked with a wide spatula. After wetting the plaster surface with a Sponge Float, create enough plaster sludge and smoothen and sponge minor unevenness. After the plaster surface has set lightly, smoothen it with a wide spatula or finishing trowel.

Drying

Provide good ventilation to ensure quick drying of the plaster. The drying time at 10 mm plaster thickness is an average of 14 days depending on the humidity, temperature and ventilation of the room. The drying time will be extended with unsuitable temperatures/air humidity.

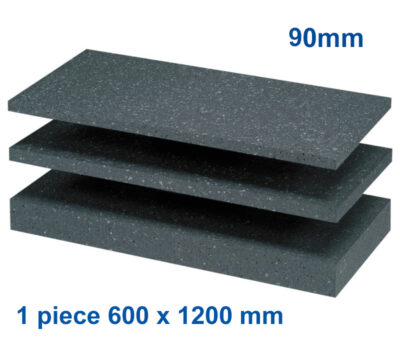

Plaster thickness

Single-layer 8 to 50 mm

Average plaster thickness 10 mm, minimum plaster thickness 8 mm. Cover tape conduits by min. 5 mm. In special cases, a plaster thickness of up to 50 mm can be applied in a single layer to a wall, however, the application of 2 layers should be considered when the plaster thickness exceeds 35 mm, as there is an increased drying time before further coatings can be applied with a single-layer. The overall drying time is reduced when the first plaster layer dries more quickly.

Double-layer ≥ 35 to 50 mm

Roughen the first layer with a trapezoid metal sheet or similar and apply. Prime with deep penetrating primer when fully dry. The next layer can be applied after the first layer is fully dry.

Substrate for tiling

Application as a single-layer in a minimum plaster thickness of 10 mm. Level and roughen wall surfaces after application. Do not smoothen or sponge the surface. Allow to dry and set fully before priming and applying a tile covering. In non-commercial bathrooms and kitchens (e.g. WC in schools, bathrooms in hotels, hospitals, residential care and nursing homes) as substrates for tiles and floor slabs, if the weight of the tiles and floor slabs including the thin-bed mortar does not exceed 25 kg/m². Use MP 75 Diamant if the weight is higher.

Ceilings

May only be plastered as a single layer and a maximum plaster thickness of 15 mm.