External Wall Insulation (EWI) using polystyrene is an effective way to improve the thermal performance of a building, reducing heat loss and increasing energy efficiency. Atlas offers high-quality insulation systems designed for durability and excellent thermal insulation. This guide will take you through the layers of EWI. We hope it’ll help you understand the system and it’s components a little bit better.

Preparations

Windows and doors should be protected to avoid damage. We offer several tapes suited for external use:

Renderers Tape by Fiberglass Fabrics

Exterior Soft PVC Tape by Deltec

Rough Surface Exterior Masking Tape by Blue Dolphin

Multi-Surface Exterior Masking Tape by Blue Dolphin

Glass can be protected with Window Film, patio with Black Membrane.

Any uneven walls should be patched up with ZW330 mortar – it dries quicker than adhesives and is designed to work well in thicknesses 3-30mm.

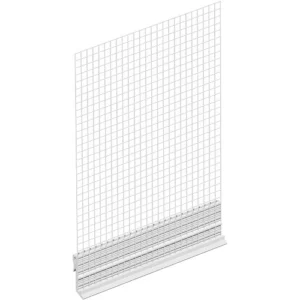

Before board installation, a Base Track (sometimes called Starting Edge) is attached to the wall. The Starting Edge provides a stable foundation for insulation boards and prevents moisture and rodent penetration.

A metal Verge Trim is often used as part of an EWI system where the roof is not able to cover the thickness of the insulation. It’s worth considering extending the roof (most grant schemes require this) as it gives a more aesthetic finish and guarantees no water will penetrate into the wall.

Wall Primers

Primers are essential and should not be skipped under any circumstances!

Every wall should be prepared before insulation. The wall should be free of mould, algae, dust. Any flaking or unstable coats (such as old render, old paint) should be removed.

All absorptive surfaces should be primed with Uni Grunt. Atlas Uni Grunt is a deep-penetrating primer designed to improve adhesion and regulate substrate absorbency before installing External Wall Insulation (EWI). Here are its key benefits:

- Enhances Adhesion – Strengthens the bond between the adhesive (e.g., Atlas Hoter U) and the substrate, preventing detachment of insulation boards.

- Regulates Absorbency – Prevents excessive moisture absorption in highly porous surfaces, ensuring even curing of adhesives and renders.

- Prevents Premature Drying – Reduces rapid water loss from adhesives, ensuring proper setting and adhesion.

- Increases System Durability – Reduces the risk of delamination or failure of the insulation system over time.

Non-absorptive surfaces such as old render, old, well bonded paint should be primed with Cerplast. Cerplast is a bonding primer based on acrylic resin and quartz aggregate. It creates a rough surface, which helps with adhesion and ensures the proper setting of adhesives.

Polystyrene

The recommended Polystyrene Thickness is 100mm. It meets the UK Building Regulations requirement of 0.30 W/m²K. We also sell 90mm, 50mm, 30mm and 20mm. Two thinnest are used around windows and doors where the use of 50mm or 100mm is not possible. We sell Graphite EPS only as it’s superior to white.

Graphite EPS contains graphite particles that reflect and absorb radiant heat, improving insulation. It has a lower λ-value (~0.031 W/mK) compared to white EPS (~0.038 W/mK), meaning thinner boards can achieve the same U-value.

Boards should be placed in a staggered pattern, like brickwork, to prevent vertical joint alignment, which can create weak points. Ensure that no four corners meet at one point to avoid cracks in the system. Trim and Fit Around Openings. Use a hot-wire cutter or fine-toothed saw to cut boards around windows, doors, and pipes. Place boards so that joints never align with the edges of openings—always overlap them for better stability. The board should have a L-shape and hug a window/door corner. Minimize gaps between boards. If any small gaps remain, fill them with narrow strips of EPS or low-expansion PU foam (never adhesive) such as Ceresit CT88 or Whiteteq.

Graphite Polystyrene is only used above the DPC. You can (and should, where possible) insulate below DPC with HYDRO EPS. Our boards are blue to easily differentiate them from other types of polystyrene. HYDRO EPS has high water resistance, durability, and compressive strength and very low water absorption.

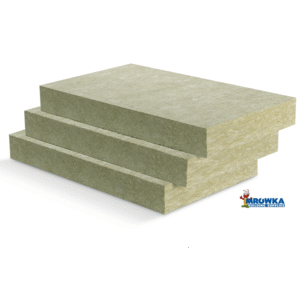

Mineral Wool

When using EPS (expanded polystyrene) insulation in external wall insulation systems, mineral wool is often incorporated as a fire break to enhance the system’s fire safety. Mineral wool is non-combustible (Euroclass A1) and capable of withstanding high temperatures without contributing to fire spread. It is typically installed in horizontal and vertical bands, particularly when two properties meet e.g. a semi-detached or terraced house. These strategically placed fire breaks interrupt the continuity of combustible insulation, helping to slow down or contain the spread of fire, thereby improving the overall fire performance of the façade system. This combined approach allows for the thermal efficiency of EPS while meeting fire safety requirements, especially in buildings with increased fire risk or where regulations demand additional protection. Mineral Wool requires K-50 adhesive.

Adhesives

We offer two adhesives, both are dual-purpose, suitable for fixing the boards and meshing. The recommended coat thickness is 2-5 mm. The adhesive should be applied to the insulation in a border-and-dot pattern.

Hoter U is a universal adhesive, suitable for both EPS and XPS boards. It’s grey, suitable under all colours from the standard pallet (SAH 400). It must be primed with the appropriate primer before the top coat. Main advantages:

- More cost-effective than K-50

- Fibre-reinforced

- Resistant to cracking

- Vapour permeable

K-50 is also a universal adhesive, it’s suitable for EPS and mineral wool. It’s perfect where a fire break is installed. It’s off-white in colour, suitable for all colours of the top coat including the intense range (SAH 401 – 480). No primer is required between the base coat and the top coat (acrylic, hybrid, silicone), which saves time on-site. Main advantages:

- Based on white cement

- Very resistant to cracking

- Fibre-reinforced

- Enhanced with polymers

- Vapour permeable

- No primer required

Mesh and beads

A fibreglass mesh layer is essential to provide long-lasting, durable insulation. It resists impact and cracks and reinforces the wall. It can be purchased in full rolls or we can cut the required amount from the roll (in increments of 1m). A mesh should overlap to avoid weak spots. The window and door corners should be additionally reinforced with a stress patch applied diagonally.

Mesh and all beads should be embedded into the adhesive in one layer.

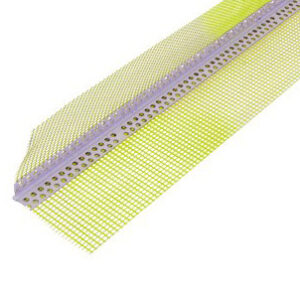

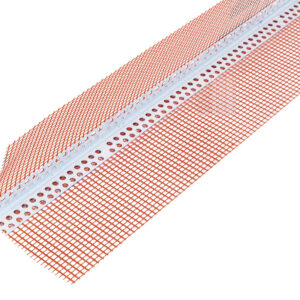

PVC corner beads are available in 2.5m and 3m lengths. In Atlas’ system, the corner profiles have a 90° angle without a lip, with the mesh on the outside of the corner, to be embedded into the adhesive layer for a secure and seamless finish. They reinforce the fragile corners and provide a straight, visually appealing line.

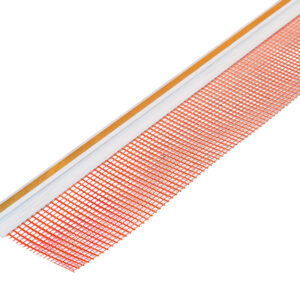

Drip PVC corners help to redirect water away from window reveals. The bead is white.

A very useful bead is the bottom mesh drip bead (sometimes also called clip-on profile with mesh) – it redirects water away from the wall and base track. The mesh helps to reinforce and blend the bead into the adhesive layer.

Window profiles have a seal and an extra protective self-adhesive strip that gets removed at the end. They provide a neater finish than stop beads or rendering up to the window. The mesh can be partially trimmed if the reveal is shallow.

A stop bead is used in EPS EWI systems to create a clean, straight edge at terminations such as window reveals, wall ends, or transitions to different materials. It helps ensure a neat finish, protects the render edge from cracking or chipping, and provides a clear separation line where the system stops, enhancing both aesthetics and durability.

Fixings

UK regulations do not always mandate mechanical fixings, but for added security and durability, insulation should be installed using both adhesive and mechanical fixings, regardless of wall height or building location. The adhesive should be completely dry before the holes are drilled. The plugs’ length should be chosen in consideration of the insulation thickness.

To reduce thermal bridging, you can use KES cutter to cut the holes for the plugs and fill them with KES covers.

If the wall has metal or timber elements, Insulation Washers with appropriate screws can be used instead of plugs for secure fixing.

Primers

Priming the reinforcing layer in an EWI system serves several important functions, ensuring durability, adhesion, and a high-quality finish. Here’s why it’s essential:

- Improves adhesion of the render – Adheres strongly to the substrate and contains aggregate (creates rough surface)

- Regulates absorption – Without priming, the base coat may absorb moisture unevenly, leading to patchy drying of the render. A primer helps prevent water loss from the render, ensuring a smooth and consistent finish.

- Enhances durability & weather resistance – KT16 Cerplast and ANX Silkon form a temporary protective layer for a façade – protects non-rendered façade against weather conditions within half a year

KT16 Cerplast should be applied before Acrylic, Hybrid (Acrylic-Silicone), Mineral and mosaic (DEKO M) renders. We can tint Cerplast to a similar colour as the top coat, which could be helpful when applying bright or intense colours. Tinting Cerplast is always recommended for mosaic renders.

ANX Silkon should be applied before Silicone render.

K-50 Stopter base coat doesn’t require a primer for the acrylic, hybrid and silicone renders. Many builders still decide to prime it to enhance durability.

The rendering work can be commenced after the mortar has dried (min. 3 days) and when atmospheric conditions correspond to the requirements indicated in the Technical Data Sheets for thin-coat plasters.

Renders

In this system the final coat is a thin coat render. Three main types are Acrylic, Hybrid and Silicone. Acrylic and Hybrid can be tinted in 400 colours, Silicone in 480. The colour chart is available here, please choose the orange rectangle 🟧 https://strefaarchitekta.atlas.com.pl/wzornik_kolorow/index.php?lang=en

Render types:

-

Building Materials, External Wall Insulation, Top Coats, Renders

Price range: £55.90 through £85.90 incl. VAT Select options This product has multiple variants. The options may be chosen on the product page

1. Atlas Acrylic Render

✅ Best for: Budget-friendly projects, areas with minimal exposure to rain and pollution.

Key Features:

- Made from acrylic resins, providing flexibility and crack resistance.

- High impact resistance, making it suitable for areas prone to minor mechanical damage.

- Vibrant colour options due to strong pigment absorption.

- Water-resistant.

- Bio protection creates unfavourable conditions for fungi and algae growth due to low water absorption and acid-alkaline reaction.

Best Used On:

- Low-rise buildings in relatively dry areas.

- Budget-sensitive projects.

- Walls exposed to moderate wear and tear but not extreme weather conditions.

-

Building Materials, External Wall Insulation, Top Coats, Renders

Price range: £59.90 through £79.90 incl. VAT Select options This product has multiple variants. The options may be chosen on the product page

2. Atlas Acrylic-Silicone Render (Hybrid)

✅ Best for: A balance of durability, breathability, and affordability.

Key Features:

- A blend of acrylic and silicone resins, offering moderate breathability with improved water repellency.

- More resistant to dirt, algae, and fungi than pure acrylic render.

- Higher flexibility than standard acrylic, reducing the risk of cracking.

- Good weather resistance, but slightly less than full silicone-based renders.

- Smoother application compared to pure acrylic.

- More cost-effective than pure silicone while offering some of its advantages.

Best Used On:

- Medium-rise residential and commercial buildings.

- Areas exposed to moderate humidity, pollution, and changing weather conditions.

- Projects where better self-cleaning properties are desired without the higher cost of full silicone render.

-

Building Materials, External Wall Insulation, Top Coats, Cement and Gypsum based Products, Renders

Price range: £67.90 through £87.90 incl. VAT Select options This product has multiple variants. The options may be chosen on the product page

3. Atlas Silicone Render

✅ Best for: High-end projects, buildings in harsh weather conditions (e.g., coastal, urban, or high-humidity areas).

Key Features:

- Made with silicone resins, offering excellent water repellency (hydrophobic effect).

- Highly breathable, allowing moisture to escape and preventing condensation issues inside walls.

- Self-cleaning properties – rain helps wash away dirt, keeping walls cleaner for longer.

- Best resistance to mold, algae, and pollution, making it ideal for damp and urban environments.

- More flexible than acrylic, reducing the risk of cracks over time.

- Generally slightly more expensive than acrylic or acrylic-silicone renders.

Best Used On:

- Coastal areas, humid climates, and urban settings with high pollution levels.

- Tall buildings where cleaning and maintenance are difficult.

- Prestige or long-term projects where durability is a priority.

-

Building Materials, External Wall Insulation, Top Coats, Renders, Painting, External Paints

Price range: £69.00 through £99.00 incl. VAT Select options This product has multiple variants. The options may be chosen on the product page

4. Atlas Cermit ND Mineral Render

✅ Best for: High breathability, eco-friendly applications.

Key Features:

- Mineral-based render with a cement-lime composition.

- Highly breathable, allowing moisture to escape, preventing trapped condensation.

- Naturally resistant to mould and fungi due to its alkaline properties.

- Requires painting.

Best Used On:

- Traditional, heritage buildings where breathability is crucial.

- Areas with high humidity, where mould resistance is essential.

- Eco-friendly projects, as mineral renders contain fewer synthetic compounds.

Atlas Salta Silicone Paint is a high-performance, water-repellent paint designed for external facades. It provides excellent protection, durability, and aesthetic appeal, making it ideal for various applications. It enhances water resistance, preventing moisture penetration while maintaining breathability. Salta improves UV resistance, preventing fading and surface degradation. It can be mixed in 400 shades (SAH 400 pallet 🟧).

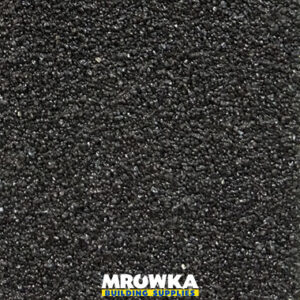

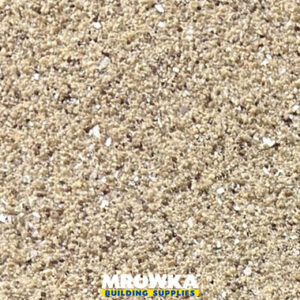

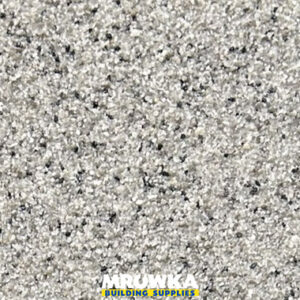

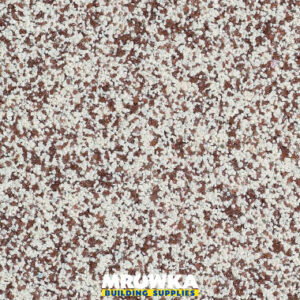

5. Atlas DEKO M (Mosaic Resin Render)

✅ Best for: Base areas, plinths, and surfaces exposed to high mechanical impact. Can be used indoors as a decorative, protective wall finish. You can use stone or brick stencils with this render.

Key Features:

- Resin-based decorative render with embedded coloured quartz aggregates.

- Highly durable and impact-resistant, making it ideal for areas subject to frequent contact.

- Water-resistant, offering excellent protection against moisture.

- Wide range of colours – a rich colour palette that also includes dark and intense colours.

- Easy to clean and maintains a long-lasting appearance due to its resin content.

Best Used On:

- Plinths and lower sections of facades that are prone to dirt or mechanical damage.

- Entrance areas, stairwells, and public spaces where durability is crucial.

- Decorative elements requiring a textured, stone-like finish.

5. Atlas DEKO M (Mosaic Resin Render)

✅ Best for: Base areas, plinths, and surfaces exposed to high mechanical impact. Can be used indoors as a decorative, protective wall finish. You can use stone or brick stencils with this render.

Key Features:

- Resin-based decorative render with embedded coloured quartz aggregates.

- Highly durable and impact-resistant, making it ideal for areas subject to frequent contact.

- Water-resistant, offering excellent protection against moisture.

- Wide range of colours – a rich colour palette that also includes dark and intense colours.

- Easy to clean and maintains a long-lasting appearance due to its resin content.

Best Used On:

- Plinths and lower sections of facades that are prone to dirt or mechanical damage.

- Entrance areas, stairwells, and public spaces where durability is crucial.

- Decorative elements requiring a textured, stone-like finish.

-

Building Materials, External Wall Insulation, Mosaic Top Coats

Price range: £76.98 through £86.88 incl. VAT Select options This product has multiple variants. The options may be chosen on the product page

![[50mm] EPS HYDRO Blue Polystyrene 1000x500mm 0.50m2](https://antbs.co.uk/wp-content/uploads/2025/02/blexport-300x300.jpg)

![[2 .5m] Stop bead 6mm PVC](https://antbs.co.uk/wp-content/uploads/2023/11/stop-300x300.jpg)

![[2.0m] Stop bead 6mm with mesh PVC](https://antbs.co.uk/wp-content/uploads/2023/11/stbd-300x300.jpg)

![[10L] Salta Silicone Facade Paint Atlas](https://antbs.co.uk/wp-content/uploads/2023/06/atlas-salta_p_1013_20240507_084115-300x300.png)